Innovations in Tissue Engineering: Bone regeneration

Electrospun fibers with hydroxyapatite

Imagine a material capable of mimicking the natural structure of human tissues, supporting repair processes, and promoting bone regeneration. Dr. Aleksandra Korbut has explored this promise. Her research on electrospun fibers made from biodegradable polymers and hydroxyapatite (HAP) opens new frontiers for biomaterials in regenerative medicine.

Biomaterials are playing an increasingly significant role in tissue engineering, especially in the context of bone tissue regeneration. Dr. Korbut's studies at Wrocław University of Science and Technology, published in the journal of Wroclaw Medical University "Polymers w Medicine" under the title “High-filler content electrospun fibers from biodegradable polymers and hydroxyapatite: Toward improved scaffolds for tissue engineering,” reveal fascinating results. Electrospun fibers from biodegradable polymers and HAP highlight new directions for developing biomaterials with broad potential medical applications.

A new generation of biomaterials

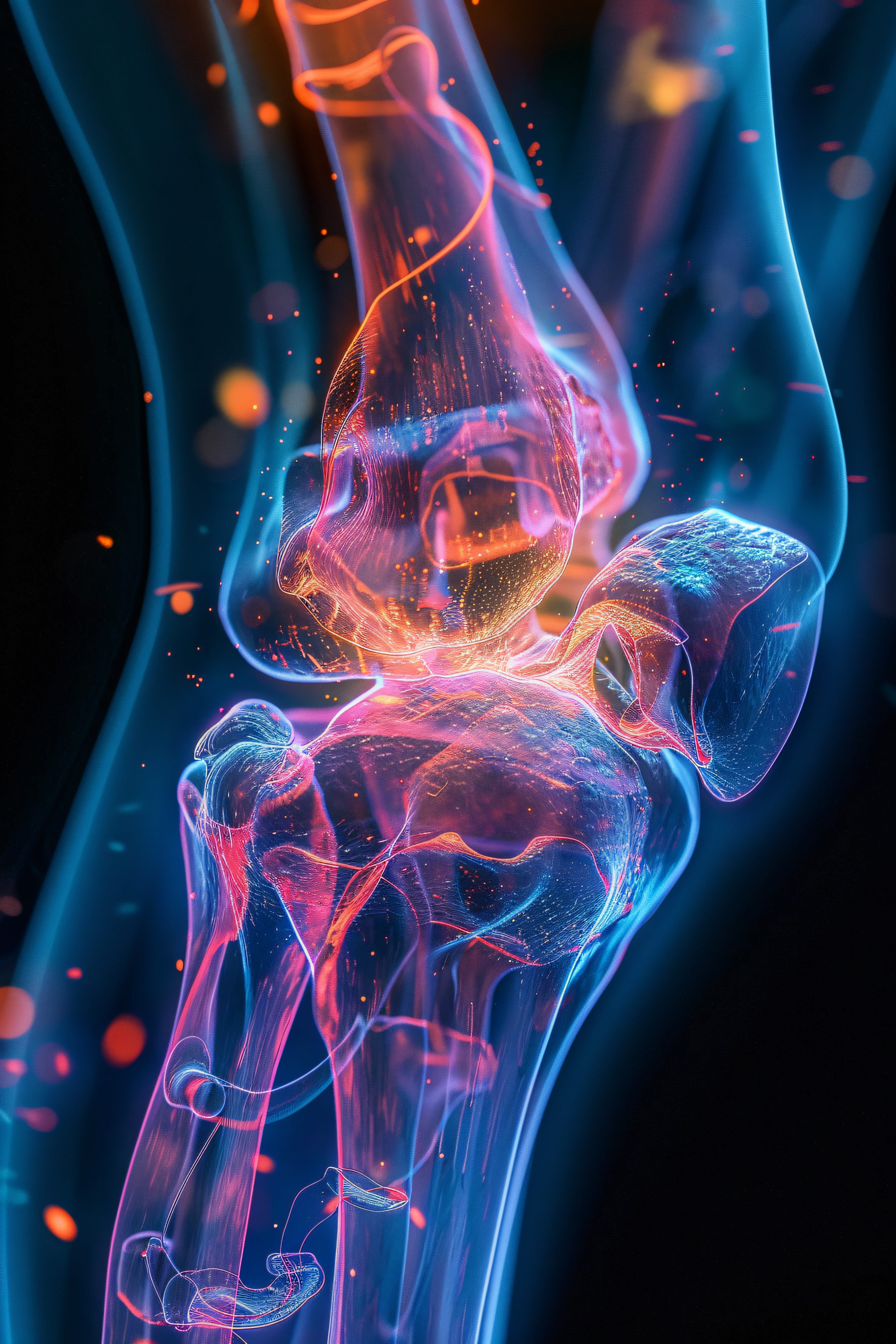

Bone regeneration is one of the challenges of modern medicine. Fractures, damage caused by osteoporosis, or bone tissue destruction due to cancer require effective treatments and innovative technologies to support the repair processes. This is where biomaterials come into play — specialized substances designed to replace or support the functions of damaged tissues.

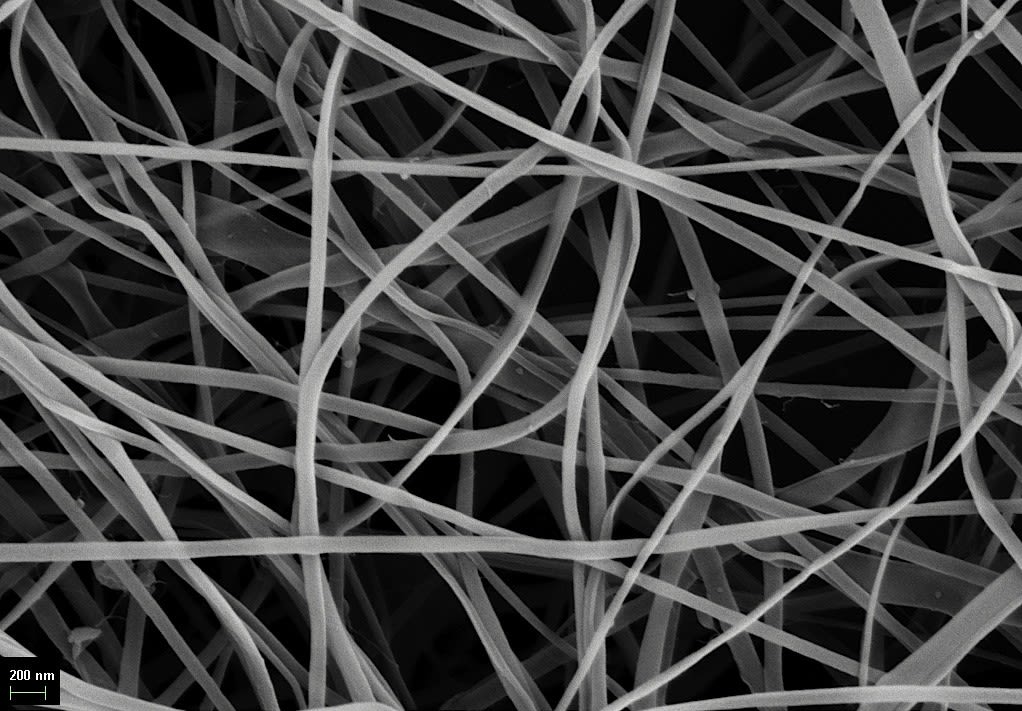

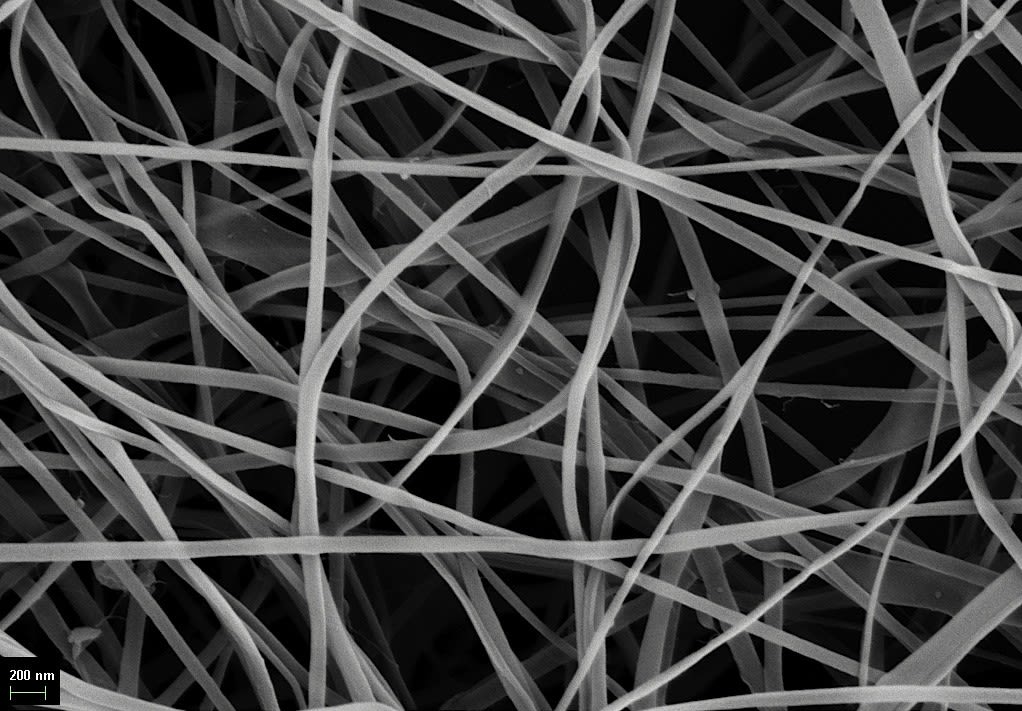

One of the most promising tools in this field is electrospun fibers. These structures are created using the technique of electrospinning, where a polymer solution is stretched by a high-voltage electric field and transformed into ultrathin fibers resembling threads. The resulting mesh mimics the natural extracellular matrix (ECM) — a structure in the human body that supports cells and regulates their functions.

Dr. Korbut's research combines this advanced technology with hydroxyapatite (HAP), a mineral naturally found in bones and teeth. As Dr. Korbut emphasizes:

"Combining biocompatible polymers with bioactive HAP has allowed us to create a material with potential far exceeding traditional solutions."

How are electrospun fibers made?

The electrospinning process might seem complex, but its principles can be likened to spinning cotton in a centrifuge, commonly used in the textile industry. Instead of cotton, however, a polymer solution is used, which, under the influence of an electric field, is transformed into thin fibers with diameters in the micron range (thousandths of a millimeter). These fibers are deposited on a specialized collector, creating a three-dimensional, porous mat.

Dr. Korbut uses two biodegradable polymers in her research: poly(L-lactic acid) (PLLA) and poly(ε-caprolactone) (PCL). These materials degrade naturally over time within the body, minimizing adverse effects. PLLA, for example, breaks down into lactic acid, a compound naturally metabolized by the human body. This feature reduces the risk of complications such as chronic inflammation.

Innovations in Tissue Engineering: Bone regeneration: podcast

Click here to listen!

Why hydroxyapatite?

HAP is a mineral crucial in building bones and teeth, providing their strength and regenerative capability. Incorporating this component into electrospun fibers enables the stimulation of osteogenesis, the process by which bone-forming cells create new tissues. Introducing HAP into polymer mats enhances biomaterial bioactivity, meaning they support regeneration and integrate more effectively with surrounding tissues.

The process of creating these fibers, however, requires precise control. One of the most important factors influencing the quality of electrospun mats is the choice of solvent. As Dr. Korbut explains:

"The type of solvent significantly determines the viscosity and surface tension of the solution, which affects the uniformity and structure of the fibers. Properly selecting the dissolving substance ensures the desired technical parameters and impacts the material's biocompatibility."

Solvents like chloroform and methanol mix well with HAP, enabling uniform mineral dispersion within the polymer matrix. As a result, the fibers produced are more homogeneous and mechanically stable. However, the toxicity of these substances poses a challenge, as their residues must be removed from the final materials, increasing production costs.

More eco-friendly alternatives, such as ethanol or water, are safer for potential clinical applications but may complicate the control of the fibers' mechanical properties. Optimizing solution viscosity and surface tension is crucial to prevent defects like discontinuities or irregularities in fiber structure.

Precise management of these parameters is vital in electrospinning, mainly when aiming to create materials with a high HAP content that retain both mechanical properties and biocompatibility.

Unique properties of electrospun fibers

The porous structure of electrospun mats allows an efficient exchange of nutrients and metabolites between cells and their surrounding environment. This is especially important in bone regeneration, where new tissues need ideal growth conditions.

Dr. Korbut's research demonstrates that introducing up to 40% by weight of HAP into fibers increases their bioactivity and improves mechanical properties, such as tensile strength. This is critical for clinical applications, where biomaterials must be as durable as natural tissue.

Alternatives and their limitations

While electrospinning is one of the most promising technologies for producing scaffolds in tissue engineering, other methods exist. 3D printing, for instance, enables precise design of macroscopic structures but fails to replicate the microscopic properties of the extracellular matrix. Freeze-drying creates highly porous scaffolds but lacks the regularity of electrospun fibers. Phase separation offers control over microstructure but lacks the versatility of electrospinning.

Scaling production and challenges

One of the most significant challenges in bringing electrospun mats to clinical practice is ensuring uniformity. Dr. Korbut notes:

"The biggest challenge in scaling production is achieving homogeneity and uniformity of the final product, ensuring consistent mechanical and morphological properties on a large scale."

Large-scale production also requires eliminating toxic solvents and meeting stringent regulatory standards, which increases costs and the time needed to introduce biomaterials into use.

The future of composite biomaterials

Further research focuses on functionalizing fibers by adding bioactive peptides or HAP nanoparticles, which could further stimulate bone regeneration. As Dr. Korbut emphasizes:

"Functionalizing fibers with hydroxyapatite or bioactive peptides can stimulate osteogenesis, significantly improving the bone regeneration process."

Hope for patients

Dr. Korbut's studies mark another milestone in the development of biomaterials. Electrospun fibers, which combine science and technology, are becoming a key tool in regenerative medicine. Their potential extends beyond bone treatment — they could also be used to repair other tissues, opening new therapeutic possibilities.

"With advanced material engineering, we can approach a revolution in treating tissue damage," Dr. Korbut concludes.

D. Sikora

FAQ: Innovations in Tissue Engineering: Bone regeneration

What is the main challenge in tissue engineering?

One key challenge in tissue engineering is creating biocompatible scaffolds that can support cell growth and mimic natural tissues' structural and mechanical properties.

What are the advantages of using biodegradable polymers in electrospinning?

Popular polymers used in electrospinning, such as polylactide, polycaprolactone, and lactic and glycolic acid copolymers, are biocompatible and biodegradable. These properties make them safe for use in the body. Moreover, their mechanical and surface properties can be easily modified to suit various therapies.

What are the advantages of electrospun mats as scaffolds for tissue engineering?

Electrospun mats are characterized by a high surface-to-volume ratio and a porous structure, enabling efficient exchange of nutrients and metabolites. This supports the regeneration process. Using biopolymers reduces the risk of long-term inflammatory reactions after implantation, as the material gradually degrades and is resorbed in a controlled manner.

What effect did adding hap have on polymer solutions?

Adding HAP to polymer solutions significantly increased viscosity, posing challenges in obtaining uniform fibers during electrospinning. High viscosity could cause needle clogging during the process. To overcome this, researchers had to adjust electrospinning parameters, such as voltage, flow rate, and the distance between the needle and collector.

What is electrospinning?

Electrospinning is a modern technique for producing fibrous structures for regenerative medicine. It involves forming fibers from a polymer solution using electrostatic forces generated by high voltage. These forces stretch the liquid, creating thin fibers deposited onto a collector, resulting in matrices resembling natural tissue structures.

Why is hydroxyapatite (hap) added to polymers in electrospinning?

Hydroxyapatite (HAP) is a natural component of bones and teeth. Adding HAP to polymers during electrospinning improves fiber properties and creates composites with enhanced characteristics. HAP increases bioactivity, stimulates osteogenesis, and accelerates bone tissue regeneration. Additionally, it facilitates implant integration with tissue, reducing the risk of rejection and supporting the formation of new bone structures.

What was the aim of the study described in the source?

The study aimed to create composite mats made of biocompatible polymers containing the highest possible amount of bioactive filler (HAP). These mats were designed to support cell growth, differentiation, and the formation of new tissue. The unique structure of mats obtained through electrospinning mimics the natural structure of tissues and, combined with the bioactivity of HAP, makes them potentially valuable for regenerative medicine.

What were the main findings of the study?

The study demonstrated the possibility of creating bioactive composite scaffolds made from biopolymers PCL and PLLA with micrometer-sized HAP particles in varying proportions using electrospinning. The researchers successfully incorporated a large amount of HAP into polymer fibers, increasing their hydrophilicity, which is beneficial for tissue engineering applications. The findings highlight the potential of polymer mats combined with HAP in tissue engineering, particularly bone regeneration. However, precise control of the electrospinning process is crucial to produce stable and durable fibers containing HAP.

Aleksandra Korbut, PhD: Research and teaching assistant professor in the Department of Polymer Engineering and Technology at the Faculty of Chemistry, Wrocław University of Technology. Conducts research related to the modification of natural polymers, the synthesis of polymeric photochromic materials and the fabrication of nano- and microstructures with different morphologies. She concentrates on the use of electrospinning technique to form fibers and biopolymer mats for regenerative medicine applications as fibrous implants. She is also focused on the fabrication of porous and solid polymer and composite scaffolds for use as bone tissue implants.

The journal "Polymers in Medicine" has been published since 1971. It is now a semi-annual, peer-reviewed, open access journal.

"Polymers in Medicine" is an independent, multidisciplinary forum to exchange scientific and clinical information. The journal publishes original papers (technical, analytical, experimental, clinical), preliminary reports and reviews considering the application of synthetic and natural polymers or biomaterials in various fields of medicine, pharmaceutics, biotechnology, veterinary science, chemical sciences and physical sciences, including, i.a., biochemistry, clinical medicine, controlled drug delivery, pharmacology, dentistry, implantology, and bioengineering.

The journal "Polymers in Medicine" is owned and published by Wroclaw Medical University, ul. K. Marcinkowskiego 2–6, 50-368 Wrocław, Poland.

Web. A. Hasiak

The material is based on the article:

High-filler content electrospun fibers from biodegradable polymers and hydroxyapatite: Toward improved scaffolds for tissue engineering

Aleksandra Korbut

doi: 10.17219/pim/196351